- About

- Membership

- Events

- Resources

- Communications

- Members Only

Boiler 101

What is a Boiler? Why use a Boiler? Where are Boilers Used? What are the major components of the Boiler System?

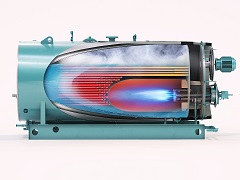

What are the basic types of Boilers? Firetube BoilerIn firetube boilers, the combustion gases pass inside boiler tubes, and heat is transferred to water between the tubes and the outer shell. Today, larger firetube boilers are over 1,500 boiler horsepower (about 50,000 pounds per hour. Firetube boilers are often characterized by their number of passes, referring to the number of times the combustion (or flue) gases flow the length of the pressure vessel as they transfer heat to the water. The turnaround zones can be either dryback or waterback. In dryback designs, the turnaround area is refractory-lined. In waterback designs, this turnaround zone is water-cooled, eliminating the need for the refractory lining. Watertube BoilerIn watertube boilers, boiler water passes through the tubes while the exhaust gases remain in the shell side, passing over the tube surfaces. Because tubes can typically withstand higher internal pressure than the large chamber shell in a firetube, watertube boilers are used where high steam pressures (3,000 psi, sometimes higher) are required. Watertube boilers are also capable of high efficiencies and can generate saturated or superheated steam. In fact, the ability of watertube boilers to generate superheated steam makes these boilers particularly attractive in applications that require dry, high-pressure, high energy steam, including steam turbine power generation. The performance characteristics of watertube boilers make them highly favorable in process industries, including chemical manufacturing, pulp and paper manufacturing, and refining. Although firetube boilers account for the majority of boiler sales in terms of units, watertube boilers account for the majority of boiler capacity. Waste Heat Recovery Boiler (WHRB)These boilers may be either firetube or watertube design and use heat that would otherwise be discarded to generate steam. Typical sources of heat for WHRBs include exhaust gases or high-temperature products from an external manufacturing process in refineries and chemical manufacturing facilities, or combustion of a waste fuel in the boiler furnace. Heat Recovery Steam Generators (HRSGs)HRSGs transfer energy from the exhaust of a gas turbine to an unfired or supplementary fired heat-recovery steam generator to produce steam. Exhaust gases leave the gas turbine at temperatures of 1,000°F (538°C) or higher and can represent more than 75% of the total fuel energy input. This energy can be recovered by passing the gases through a heat exchanger (steam generator) to produce hot water or steam for process needs.

|